|

Power Distribution Cabinet Powder Coating

Collect

DESCRIPTION Power distribution cabinet powder coating is a free-flowing, dry powder that is applied to metal to provide a high-quality and chemical-resistant finish. When the coating is exposed to heat, the plastic particles melt to form a high-durability film. Powder New Enclosures offers in-house powder coating in a wide range of colors, with an excellent color match system, to meet all of your customization needs.

Power distribution cabinet powder coating makes up the majority of powders used in industry for a wide variety of decorative and protective applications; this is due to the nature of thermosets versus thermoplastics. Thermosets—once cured and cross-linked—will not melt and flow again if subjected to heat a second time. Thermoplastics, however, will continue to melt and flow repeatedly if exposed to heat.

Power distribution cabinet powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form. Powders can be formulated to meet a wide variety of appearance or performance characteristics; this includes film thickness, gloss, texture, color, and the performance (hardness, chemical resistance, U.V. resistance, etc.) of the coating. Powders are composed of several different components, blended together at high speed to form the final product. Once blended, the mixture is extruded, cooled, and then chipped into pieces. These chips are then ground to a very specific particle size distribution, depending on the application, and screened to ensure larger chips do not pass through.

ADVANTAGES ●Difficult shapes can be coated ●Film thickness between 30-250 ●Simple and low cost for automation ●Changing color is relatively simple ●No pre-heating of components required

SPECIFICATION

STORAGE CONDITIONS ●Temperature: ≤35℃ ●Humidity Conditions: Dry, Cool and Ventilated ●Storing Requirement: Cannot be piled up over 4 cartons; ●Seal the PE bag after using; ●Away from VOC, fire and heat; ●Validity: 6 months (If the parameters are tested to be qualified, the product still can be used expire date)

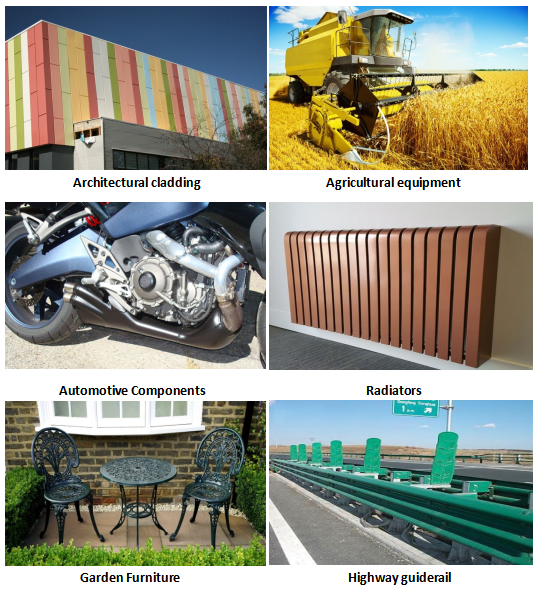

OTHER APPLICATIONS

|

||||||||||||||||||||||||||||||||||||||||||||||||||||