|

Polyurethane Resin Powder Coating

Collect

DESCRIPTION Polyurethane resin powder coating is similar to their polyester counterparts. Polyurethane is more widely used in the U.S. whereas polyester is predominant in Europe. The principle differences are that polyurethane resin powder coating is harder but less flexible and less impact resistant than polyester. It also has a better flow, the downside of this being worse edge coverage. Polyurethane is more resistant to solvents so most thermoset antigraffiti powders use this technology.

Powder New polyurethane resin powder coatings exhibits properties similar to epoxy powders, but also offer exterior durability and are often more ‘overbake stable’ than epoxies (though not as good as Polyester TGIC powders). Disadvantages include a more restricted cure range, potential odor and smoke from cure, and significantly higher cost. Polyurethanes are most commonly found in exterior functional applications where chemical exposure is a concern

ADVANTAGES ●Exterior Durability - Excellent exterior durability is possible with either chemistry. Standard grade and “Superdurable” polymers are available in both polyester and polyurethane varieties. The superdurable products have the potential to maintain appearance and film performance for up to 6 or 7 years in south Florida environment. ●Hardness and Abrasion Resistance - Polyesters are typically somewhat softer and less abrasion resistant than their polyurethane counterparts. The additional crosslinker inherent in a polyurethane powder formulation is responsible for the added performance. Using the somewhat archaic pencil hardness test, polyesters clock in at H hardness whereas polyurethanes can achieve H to 5H depending upon the specific formulation. The higher hardness products typically sacrifice mechanical flexibility. ●Low Gloss and Matte Finishes - Polyurethanes can be formulated from matte to high gloss with very good to excellent coating performance. Polyesters are more difficult to formulate in lower gloss and film performance can be reduced with some of these formulation schemes.

●Chemical Resistance - Both chemistries provide fairly good chemical resistance however polyurethanes significantly outshine polyesters if formulated appropriately. In fact a highly crosslinked polyurethane powder coating provides chemical resistance that rivals epoxy powder performance. ●Cure Response - Low temperature cure is much easier to develop in a polyester than a polyurethane powder coating. A couple caveats need to be noted. HAA polyesters are more difficult to catalyze than TGIC based polyesters. HAA polyesters can cure as low as 325°F whereas TGIC polyesters can be formulated to cure at temperatures as low as 250°F. Polyurethanes bottom-out around 300°F. ●Film Thickness - One peculiarity of polyurethanes is the need for a chemical blocking agent in the crosslinker. These blocking agents volatilize out of the coating during the bake cycle. Blocking agents make the chemistry work best (balance of reactivity and cure) but also can create pinhole defects in thick film coatings. Hence polyurethanes are difficult to apply successfully at film builds greater than 5.0 mils, whereas TGIC based polyester powders can be applied at upwards of 10 mils. On the other hand polyurethanes inherently provide very good film smoothness at thin films (>1.5 mils). ●Cost - In general, you will pay more for a polyurethane powder coating as compared to a polyester based powder. That said, the powder formulator can cheapen a polyurethane powder product by taking a substantial amount of quality out of the coating.

SPECIFICATION

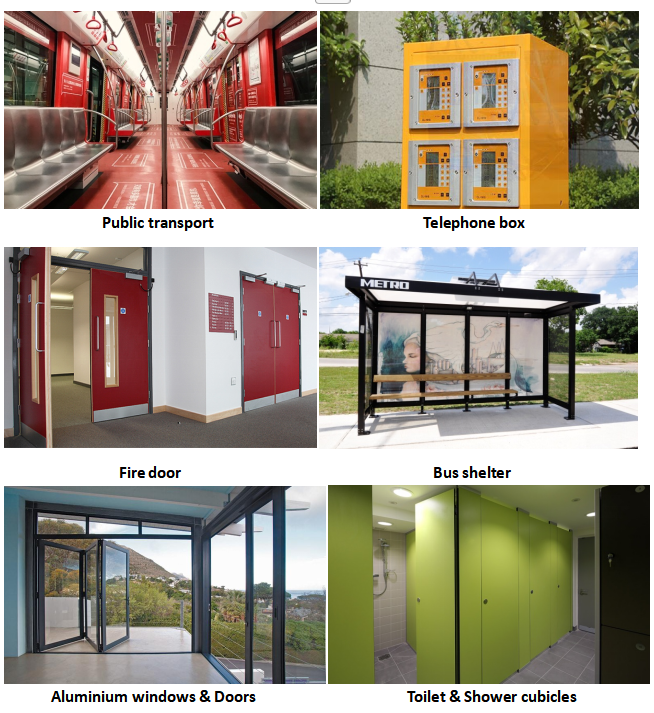

APPLICATIONS

|