|

Acrylic Resin Powder Coating

Collect

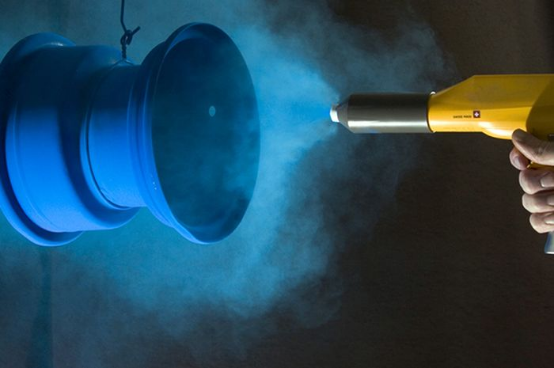

DESCRIPTION Acrylic resin powder coatings are used primarily in the automotive sector as clear coat materials. Acrylics make for a very smooth clear coat with exceptional clarity. They also provide a very hard surface that is highly chip-resistant. These types of glycidyl methacrylate acrylics are highly contaminating and should not be sprayed side by side with other powder coatings. Separate powder booths and air are a must in an enclosed area to avoid contamination, which will result in craters in the finish of parts using the other powder chemistries.

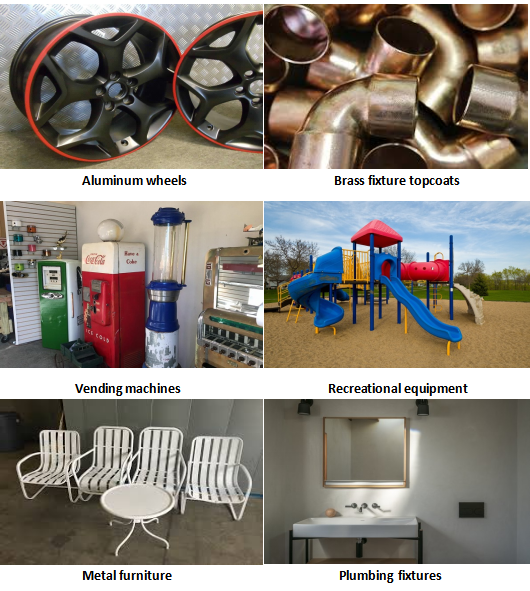

Acrylic resin powder coating displays excellent film appearance and clarity in demanding clear coat applications such as auto- motive full-body clear coats, automotive wheels and parts and brass hard- ware. These powders contain acrylic resins crosslinked with a long-chain dibasic acid such as Dodecanedioic Acid.

The good resistance properties, durability, and smooth appearance make acrylic powder coatings ideal for exterior applications. Clear acrylic powder coatings possess excellent clarity and are frequently used for products with high quality standards.

ADVANTAGES AND DISADVANTAGES ●Outstanding smoothness ●Excellent weatherability ●Good chemical resistance ●Optical clarity and water-white color ●Poor impact resistance and flexibility ●High cost ●Difficult to pigment into different colors ●Cross contamination into other chemistries is often a problem ●Poor storage stability

SPECIFICATION ●Supper Matt (<10%), Matt (<20%) ●Wrinkle/Sanded/Netted/Crackle/Crocodile/Hammer/Woodgrain/Metallic/Pearl/Antique ●RAL color, Pantone colors full color range is available ●Specific gravity :1.2 ~ 1.8g/cm3 up to colors ●Particle size distribution:100% less than 100 microns(depending on the specific indicators art effects may be, according to the special requirements of painting adjusted) ●Level of liquidity:24 ~ 27 mm

STORAGE CONDITIONS Stored in lessthan 30 °C, ventilated, dry, clean room, not near the fire source, heating,avoid direct sunlight, the product in the transport should be to prevent rain,sun, prolonged sun exposure.Storage products in line with the above conditions,since the date of production, effective storage period is 6 months.Overthe storage period may be re-tested and the results were consistent with, canstill be used. APPLICATIONS

|