|

LPG Cylinder Powder Coating

Collect

DESCRIPTION As a common resource, the usage of LPG (liquefied petroleum gas) has increased greatly in recent years. The demand for LPG cylinder is also increasing with the extensive use of LPG. In the process of manufacturing LPG cylinders, final surface finishing is also very important except selecting high-quality materials. Qualified surface treatment is very wear-resistant, corrosion-resistant. It can also prolong LPG cylinders’ service life effectively. Then, how to make the perfect surface treatment of LPG cylinders? LPG cylinder powder coating is an ideal solution. The film cured on the surface of LPG cylinder powder coating is very strong, and this treatment is more environmentally friendly than ordinary painting. Powder color can also be selected to meet the requirements of the appearance.

LPG cylinder powder coating is a process of coating metal with powder form and baked to a fluid state to bond it to the metal surface. This process can create a harder finish that is tougher than conventional paint. It is mainly used for coating metals, such as appliances, automotive parts, and other hardware. Since it is not a liquid product, it requires no solvent to keep the binder and filler components in a liquid suspension form. It's very friendly to environment, easy to use, cost effective, and tough.

ADVANTAGES ●A smooth unbroken cylinder surface can be cleaned easily ●Surface treatment protects against corrosion ●Use manpower for cylinder maintenance in quiet periods ●In-line wet painting booths ●Reduction in procurement of new cylinders ●Fully automatic powder painting plants with overhead conveyor system and loading onto or unloading from chain conveyor ●Nice-looking cylinders have high market value ●End-users prefer newly painted cylinders ●Surface treatment extends cylinder lifetime ●Distributors and end-users treat newly painted cylinders with care

SPECIFICATION

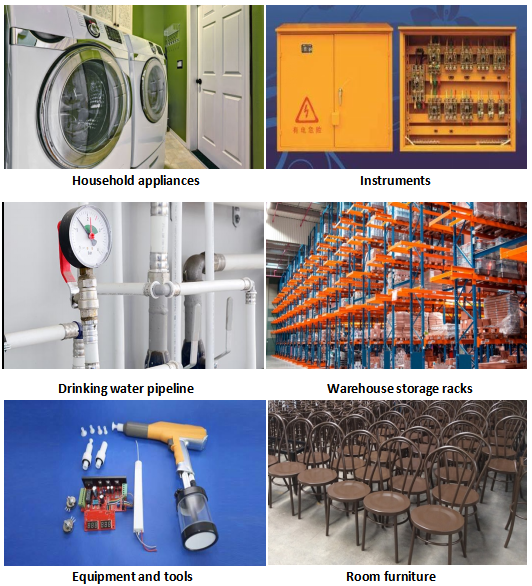

OTHER APPLICATIONS

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||