|

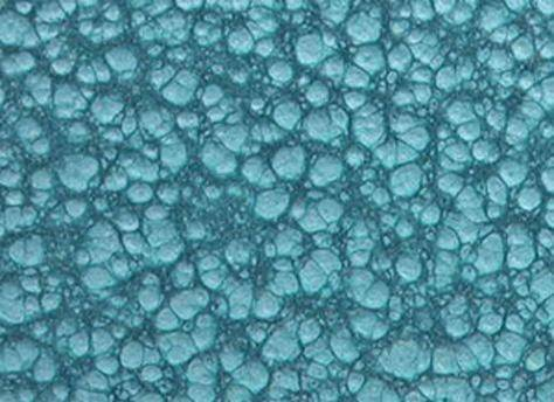

Hammer Finish Powder Coating

Collect

DESCRIPTION Powder coating is a type of coating that is applied as a free-flowing, dry powder. The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form. The powder used in the process is a mixture of finely ground particles of pigment and resin, which is electrostatically sprayed onto the surface and is then cured under heat to allow it to flow and form a “skin”. The charged powder particles adhere to the electrically grounded surfaces until the powder is heated and fused into a smooth coating in the curing oven. The result is a uniform, durable, high quality and attractive finish. Powder coating is one of the fastest growing industrial finishing technologies today.

Hammer finish powder coating is an advanced method of applying a decorative and protective finish. This type of powder coating provides excellent toughness, durability, thickness and decorative effect. This textured surface is more resistant to abrasion, chipping, scratching, fading, chemical corrosion and wearing than other finishes. It will seal the trailer well from the corrosive action of harsh environment conditions. It is the longest lasting and most color-durable quality finish. Colors stay bright and vibrant longer. It is also designed for hiding surface imperfections. Now you can have excellent performing finish that not only does the job but also looks great.

Hammer finish powder coating is environmentally friendly, in a way that would be impossible to achieve with alternative coating processes. Powder coatings do not emit (many) volatile organic compounds (VOCs) and therefore have a much reduced impact on the environment. ‘Overspray’ from powder coating can be recycled and so almost all of the coating materials can be used.

SPECIFICATION

PHYSICAL PROPERTIES ●Specific gravity :1.2 ~ 1.8g/cm3 up to colors ●Particle size distribution:100% less than 100 microns (depending on the specific indicators art effects may be, according to the special requirements of painting adjusted) ●Level of liquidity:24 ~ 27 mm

CURING CONDITIONS 180 °C ~ 200 °C (work piece temperature), 10-15 minutes

AVERAGE COVERAGE 8-12 square meters / kg, thickness 60 microns (100% of the powder coating utilization rate) PACKING Outside carton lined with two layers of polyethylene bags, each containing 20 kg net weight.

STORAGE AND TRANSPORT Stored in less than 30 °C, ventilated, dry, clean room, not near the fire source, heating, avoid direct sunlight, the product in the transport should be to prevent rain, sun, prolonged sun exposure.Storage products in line with the above conditions, since the date of production, effective storage period is 6 months.Over the storage period may be re-tested and the results were consistent with, can still be used.

HEALTH AND SAFETY Coating powder is a non-toxic products, but should be avoided in the course of inhalation of dust.Proposed operators wear appropriate dust mask, glasses.If possible, try to avoid long-term skin contact with powder coating

HAMMER FINISH POWDER COATING COLOR SAMPLES

Hot Tags: hammer finish powder coating, China, manufacturers, suppliers, factory, customized, wholesale, buy, in stock, made in China, Metallic Powder Coating, hyper silver powder coat, black chrome powder coat, Antique Copper Powder Coating, copper powder coat, Wrinkle Finish Powder Coating |