|

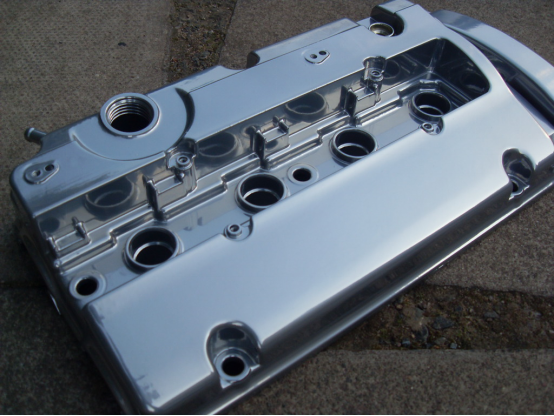

Mirror Chrome Powder Coating

Collect

DESCRIPTION Mirror chrome powder coating is a process that is used in the automotive industry to protect metal parts. Powder coating is often applied to car, truck, or motorcycle parts. This process involves putting a dry powder onto a metal surface and then baking it until it forms a permanent, protective layer. The powder coating serves to prevent rust or corrosion on the auto parts. If you have a motorcycle, you may wonder what you can do to protect those beautiful, shiny chrome parts. Chrome looks great, but not after it has been scratched up or exposed to the elements and gotten rusty. This is how to powder coat chrome.

Mirror chrome powder coating needs to be applied to a surface that it can grip. Chrome is too smooth and slippery; powder coating won’t slip. So the first step in powder coating chrome is to strip the chrome surface. Before you can apply the powder coating, you must sand blast the parts to make sure that any chrome surface residue has been removed. Don’t worry about losing that shiny luster; you can purchase powder coating that looks just like chrome when it is finished. This way, you have the protection of powder coating and the appearance of chrome. It’s the best of both worlds.

It is also important to pretreat the parts before applying mirror chrome powder coating. This will ensure that the parts are completely clean and prevent the powder coating from flaking off after application. If you plan to take the piece to a shop for professional powder coating application, be sure to carefully choose the shop that will apply the powder coating in order to be sure that the process is performed under high quality standards. Next, preheat the chrome piece in your oven. Set the oven to 400 degrees, and heat the item for about ten minutes. Then hang the chrome piece so that you can cover every angle. Load the powder into the gun, and adjust the air pressure setting. Now evenly spray the coating over the chrome piece. Be careful to cover the piece from all angles, and apply a second coat if necessary. To finish, bake the item in the oven at 400 degrees for 25 minutes. If you are working with a particularly large piece, turn the oven up to 450 degrees.

FEATURE ●High-Tech, Bonded Polyester-TGIC formulation for tarnish resistance ●Cures at 400°F ●Our most reflective “chrome” powder ever ●Topcoat with Super Gloss Clear for best results ●A perfect base under our translucent or candy powders for custom finishes

SPECIFICATIONS ≯ Color: Chrome ≯ Gloss Level: Gloss ≯ Cure Temperature: 400 Degrees ≯ Cure Time: 20 Minutes after flowout ≯Powder Type: High-Tech, Bonded Polyester-TGIC ≯Finish: Smooth ≯ Coverage: 1/2 lb. of powder is approximately 10-20 sq. ft.

INSPECTION CHART

MIRROR CHROME POWDER COATING COLOR SAMPLES

Hot Tags: mirror chrome powder coating, China, manufacturers, suppliers, factory, customized, wholesale, buy, in stock, made in China, powder coated metal, wrinkle red powder coat, Antique Copper Powder Coating, powder coating over chrome, metal flake powder coat, chrome powder coat |